This update is a brief synopsis of a presentation given at the Toddington Standard Locomotive Ltd Annual General Meeting on 29th November 2025. Copies of this report have also been circulated to Shareholders that were not able to attend in person.

Despite our best efforts the overhaul of our boiler is proving to be a challenge, with increasingly more additional work being discovered as the boiler is dismantled. We had already reported the need to replace the lower sections of the sides of the copper firebox due to extensive star cracking around most of the stay holes in the copper. We were also aware that the previous repairs to the laps in the copper Doorplate were a cause for concern. It was agreed with the boiler inspector that the copper Doorplate should be removed to enable us to examine the quality of the previous repairs done at Eastleigh in 1964. There were also a few localised areas around the Firehole door that needed to be built up with copper weld. Leaky Finders decided to carry out the weld repairs around the Firehole door before removing the Doorplate as the surrounding stays and rivets would ensure the copper did not distort during the welding process when the localised heat from the welding can cause the copper to deform if not held firmly in place. Soon after welding was started, Leaky Finders contacted me to say that what looked like blow holes were appearing in the copper plate around the door ring rivet holes. Having never seen this issue before, it was agreed that welding work should be paused and the copper Doorplate removed to see exactly what was going on.

Removal of the copper doorplate confirmed our fears that the platework around the Firehole door joint was riddled with cracks, and the welding had caused them to open up becoming cavities below the surface of the platework. Further examination of the replacement lap sections fitted by Eastleigh showed the penetration, and quality of the weld to be even worse than first feared. Star cracking radiating from many of the stay holes like that discovered in the firebox side sheets was also discovered. With copper welding being a very expensive exercise, due to the helium shielding gas and copper filler rods the costs to try and repair the Doorplate could be as much as 75% of the cost of a replacement, and there may still be unseen issues in other parts of the platework, that could cause us trouble in the future. We were fortunate to discover that the NYMR has a former for flanging this item and as it is almost identical to the 80xxx class locos it could be used. They have kindly agreed to let us use the former in return for a donation to one of their locomotive appeals, the fact that we don’t need to manufacture a former has saved us a considerable amount of money and is a great example of locomotive owning groups working together.

Having taken all the above findings into account, we are planning to renew the copper doorplate as we feel this is the best use of our finances. As there is a 12-week lead time to deliver the copper, we have already placed the order which hopefully should arrive in the UK early in 2026.

You may recall that I previously reported that ultrasonic inspection can not be used as a reliable method to detect flaws in the steel due to the laminations present. The removal of the Doorplate has enabled us to see the waterside of the steel Backhead. To save money our dedicated team of volunteers have been traveling to Devon and needle gunning the inside of the boiler, to remove the build-up of scale. The waterside of the Backhead was needle gunned which enabled a Magnetic Particle Inspection (MPI) to be carried out by a Non-destructive testing specialist.

First impressions were that it appeared to be in very good condition, the scale buildup seeming to have protected the steel from excessive corrosion. Even the lower section near the foundation ring which is prone to grooving looked better than expected. Unfortunately, this initial hope soon turned into more bad news when the MPI testing was carried out. What they discovered was a series of cracks running almost top to bottom between the stay holes adjacent to the corners. There was also evidence that other stay holes across the Backhead were beginning to suffer the same problem.

Whilst it would potentially be possible to weld up all these cracks and to install larger stays connecting the Backhead to the new copper Doorplate, the issue of the laminated steel would remain. When the boiler inspector visited us to discuss the issue of lamination, his advice was to devise a long term plan to replace sections of the steel in the boiler during future overhauls to eradicate as much of the laminations as possible. As boiler examination now relies heavily on NDT techniques the presence of laminations in this area of the boiler (known to suffer issues) could cause us complications when carrying out future testing. In addition to the above it seems ridiculous and a waste of money to renew the copper doorplate only to ream out all the stay holes to a large size, reducing the life of the repairs significantly.

The only sensible answer is to renew all or part of the boiler Backhead, which is currently where the problems lie. The best, and our favoured repair, is to replace the complete Backhead below the level of the firebox crown, known as a ¾ repair. Unfortunately, the 76xxx class locomotive has a different Backhead to that fitted to the 80xxx and 75xxx class 4 locomotives. A former for these classes does exist at the South Devon Railway, but whether it can be modified to accommodate the 76xxx class boiler is currently in doubt. To the best of our knowledge, no 76xxx class locos, or the Class predecessors the LMS Ivatt 2-6-0 class 4 locos have had a replacement Backheads in preservation, so we would be the first. As I write this article, we are still awaiting a formal response from South Devon Railway Engineering as to whether they can supply, and if so what the costs would be. We are also talking to Mendip Steam, who flanged our new throatplate and front tubeplate, to enquire whether they could make a former to the exact shape of our existing Backhead and flange a replacement.

There is an alternative repair which could be done and that is to cut out the areas of the Backhead where the stays are fitted and weld in new platework. This would eradicate the cracks and enable first size stays to be fitted, but we would still have laminated steel in the corner radiuses which could cause issues when welding in the new platework. The amount of linear welding would also be considerable, so the costs of welding would be greater. Currently we are considering this repair to be a last resort if the costs of a replacement Backhead prove to be considerably more than expected.

So where does this leave the boiler overhaul now?

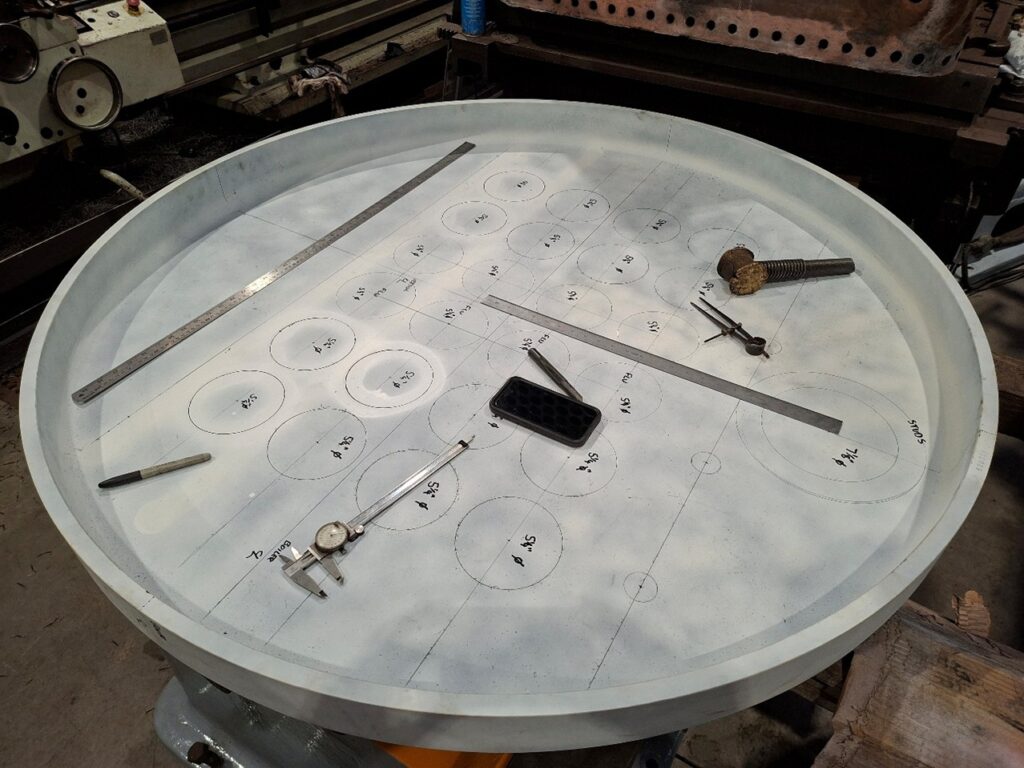

We have had a fantastic response to our boiler appeal this year and that has been significantly boosted by the “Match Funding” initiative, so we have a lot to be thankful for. A lot of work has been done on the boiler, the new front barrel section has been fitted, the new tubeplate has been flanged and is being marked out and drilled. A new throatplate piece has been formed ready to replace the lower section under the boiler barrel. The foundation ring has been removed and weld repairs carried out, and a significant amount of careful stripping of parts of the boiler carried out. New C107 copper sheet has been sourced ready to be fitted in the firebox, together with copper material for stays and patch screws stockpiled.

With the necessary additional boiler work now identified, the cost to complete the boiler overhaul will inevitably rise. We are in the process of obtaining revised quotations from Leaky Finders for this additional work, but it is far from a simple process. It is currently being held up by the issue of the replacement Backhead, and whether a cost-effective replacement is possible. I was hoping by now to be able to give you some definitive costs, but we are just not yet in that position. Rather than speculate the TSLL board would prefer to hold back and let you know when we have the revised costings.

This latest news is obviously not what any of us wanted to hear or were expecting. We were led to believe by many well-respected steam locomotive boiler experts that have examined 76077’s boiler over the last 30 years, that it was in relatively good condition, but that was from what could be seen. It’s turned out to be the parts that couldn’t be seen or were supposedly repaired in 1964 that are causing the issues.

As engine owners we have just been very unlucky. Both Rory at Leaky Finders and I have been involved in this profession for many years, and we have never seen such a catalogue of issues on what is a relatively new boiler. Rory commented that the condition of the boiler gives the impression it’s done 100 years in service not 16 years. Despite this set back we will push on and get the job done, although clearly it will take a lot longer than first thought. Because of the additional repairs, it should become one of the best boilers in preservation and keep 76077 and steam alive for many more generations to come.

To demonstrate that the work on 76077’s boiler will be money well spent, recently another of the locomotives based on the GWSR, 7820 Dinmore Manor, had its boiler lifted out of the frames after 11 years of service in preparation of its 3rd overhaul in preservation. Like ours that boiler had an extensive list of repairs carried out during its last overhaul, and the work done then still looks to be in excellent condition. This is a testament to the quality of the GWSR’s water treatment and the dedicated team that look after and monitor the system. The easy gradients on the GWSR and the quality of the training of the locomotive crews have also played an important role in looking after that boiler during the past 11 years, all very encouraging for 76077’s operational future.

Finally, I must say a huge thank you to all our shareholders and supporters who have contributed to our project, it is so greatly appreciated. Special thanks go to our anonymous benefactor for their gesture of support for the project, which has made such a positive difference despite the recent boiler issues. We are definitely not out of the woods yet, and we will have to find ways to raise additional funds. The TSLL board are working on this but would welcome any suggestions from you. I realise that with the rising costs of living many of us are now facing even more financial pressures at home, but if you are able, please continue to add to your shareholding in 2026.

Finally, I wish you all a Merry Christmas and a happy and heathy 2026.

Andrew Meredith

TSLL Engineering Director