One of the most frequent questions I’m asked is “what will you do about building a tender for 76077?”. In this article I will try and explain the history that resulted in the loss of our tender and what options there are to provide our locomotive with a new one.

First of all, it’s worth explaining the tenders that were attached to members of the Standard class 4 2-6-0s. As originally designed, the engines were equipped with the BR2 tender carrying 6 tons of coal, 3,500 gallons of water and a water scoop so water could be collected from water troughs while on the move. Following practical experience, from no. 76044 onwards the locomotive cab and tender designs were changed, creating the BR2A type (with identical water and coal capacity). The principal difference was that the newer design incorporated a fallplate and gangway doors – the early type did not have these features, the gangway door being fitted to the locomotive along with a draught-excluding canvas that was not very effective, draughts swirling coal-dust around the cab being a problem for the footplate crews. An exception to the fitting of BR2A tenders was for locomotives 76053-69 on the Southern Region, which had the larger BR1B attached with a coal capacity of 9 tons and 4,725 gallons of water. For these tenders, which also had a fall plate and gangway doors, a water-scoop was not provided because the SR had no water troughs. However, water softening equipment was fitted to help deal with the hard water on the south-western division of the SR. The larger tenders therefore gave their locomotives greater range without the need for stopping to take water.

As many readers will be aware, our locomotive lost its original BR2A tender whilst languishing in Barry scrap yard waiting to be saved. That tender, no 1462, was purchased to run with 76017, the first of the 76xxx locomotives to be restored to working order. 76017 was designed to run with the earlier BR2A tender, and that acquired from Barry has had to be modified to fit the locomotive. 76017 which had lost its own BR2 tender when it was sold into industrial use. Being of very strong construction and fitted with roller bearings many of the BR Standard tenders were sold on to Briton Ferry steelworks as ingot carriers. These tenders had the tanks cut off and literally put into the melting pot, while the centre wheelsets were removed to allow them to go around the tight curves in the complex. Brackets were also attached to carry the heavy steel ingots around the site. When the steelworks closed several restoration groups managed to buy a suitable chassis or individual components enabling them to rebuild a tender to run with their locomotive. Unfortunately, by the time 76077 was rescued from Barry all the usable parts had already been purchased by other owning groups.

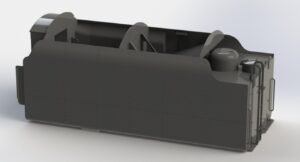

Chris Hinton, 76077’s previous owner, managed to acquire a spare set of GWR Hawksworth tender frames (coincidently these were purchased from 7903 Foremake Hall Group after they managed to source a much better set of frames from Swindon works for their loco). Chris’s aim was to modify the Hawksworth frames to provide a tender chassis for 76077. Chris also managed to secure 6 wheelsets from class 40 diesel locomotives, which have roller bearing axle boxes. The plan at the time was to install these wheelsets into the modified GWR tender frame and then build a new tank to fit on the frames. In the mid-1990’s Tyseley Locomotive Works were looking for a set of tender frames to pair with GWR Castle class 5043 Earl of Mount Edgcumbe and offered to provide Chris with a full set of steel plate work for a BR standard tender frame in exchange.

Before I start explaining the pros and cons of the different tender designs, I thought I should explain the process of building what is basically a new railway vehicle. There will be people reading this article thinking that as we are only aiming to run the loco on a heritage railway at a maximum speed of 25mph, we can just alter designs to accommodate existing or available parts to suit, but that is simply not the case.

Heritage railways now come under the jurisdiction of the Office of Road and Rail (ORR) and are subject to the Railway and Other Guided Transport Systems (ROGS) safety regulations. Currently, however, railway vehicle construction is still subject to ‘grandfather rights’. This means that if we build a new vehicle to a proven design we do not need to demonstrate that the design used is fit for purpose. This is only the case if we stick to using the original construction techniques and materials. In practice this is not always possible as grades of material or manufacturing techniques have changed over the years, but where design changes have to be made, it is much easier to demonstrate that a single particular component has the mechanical attributes to perform its intended role rather than a totally new design. Whilst feasible, the idea of producing a new design or a heavily modified design incorporating available components, adds considerable time and costs (ie obtaining design approval) to the project.

The BR2A tender

Our loco was originally coupled to a BR2A when in BR service, so it would seem to be a logical decision that we build a replacement to this design. The BR2A tender is historically correct for the locomotive and the cut down sides would be beneficial to tender-first running. The 2A frames being shorter in length had small 10 ½” axle boxes fitted with a 5” roller bearing. These boxes are much smaller than those obtained with the class 40 diesel wheels, so in addition to other unique parts, we would have to manufacture new axle boxes for this tender design. This would involve new patterns, castings, machining, and replacement bearings to be sourced adding extra complexity and considerable costs to the project. Unfortunately we are the last BR standard loco to be restored that historically could run with a BR2A tender so collaboration with other locomotive owning groups to produce these parts is not an option. In short, engineering-wise, we would have to go it alone.

Should we consider the BR1B design?

Historically, a number of members of the BR Standard class 4 2-6-0s were equipped with a much larger BR1B tender. With its greater water capacity the BR1B tender would enable our locomotive to operate a full day’s service on the GWSR without the need to refill the it. With its higher coal capacity it would also mean that the locomotive could run for two days before the coal needed replenishing, meaning we wouldn’t need to top the tender up every night. With the growing concerns of the future coal supply, the larger tender would lend itself to easier fitment of an oil tank should oil firing eventually be forced upon us (we currently have no plans to pursue this, but it might need to be considered in the longer term). Running with a BR1B tender (which were common amongst the SR-allocated members of the class), 76077 would be unique amongst the surviving BR Standard 76xxx loco’s and as such would recreate a lost piece of railway history. This unique appeal may also make the loco more popular as a guest at railway galas across the country. The biggest factor to consider with the new build tender is the cost of construction, this is where the engineering arguments come into play.

Although both types of tender were deemed ‘standard’, the 2A and 1B chassis were in fact dimensionally very different. The axle boxes that came with the Class 40 diesel wheels are almost identical to the 1B design, so can be easily incorporated into the 1B frames without any significant design modification. Already one new-build 1B tender has been built for 73156 and another using the same diesel loco axleboxes is at an advanced stage of construction. Drawings and patterns for many of the parts required are also available for us to to use. There are also plans to build three more tender chassis that have the same frame design as the 1B, for example 92134, 92207 and new build 72010 Clan Hengist so there are great opportunities to share experiences and costs between owning groups. We have also been offered the use of a 3D CAD model for the 1B tender and using this model we can check the parts fit together before metal is cut. Individual CAD drawings can be called off for each part, the steel can then be profile-cut and delivered ready for assembly. As well as allowing the use of his work the designer has very kindly offered his time to help with the project if the 1B design is chosen. The current TSLL engineering team is limited in number so this offer of help would be of significant benefit to us.

Whichever tender we construct we will need new wheels, as the class 40 diesel wheels are too big in diameter to fit in the frames without modification. The larger wheels would also cause issues with the vehicle ride height, spring arrangement and the brake system, all major safety critical items, so independent design approval would need to be obtained even if a satisfactory engineering solution could be found.

Fortunately a pattern for the original spoked design of wheels exists, and we could hire this pattern to have our own wheels made. This would involve having the wheels cast, NDT tested (we don’t want cracked spokes etc), machined and pressed onto the axles and then tyres machined and fitted. This would obviously be an expensive exercise. The other option which I am currently perusing is to source plain disc wheels, which are still manufactured for modern rolling stock, and press these on to the existing class 40 axles. The design of both tenders with their deep side frames would almost totally conceal the change of wheel type. These wheels being manufactured to modern standards, and supplied by approved manufacturers would enable this design change to be easily justified.

The cost of building a new tender is estimated around £200,000, depending on the design chosen and the amount of voluntary labour used in its construction.

As I’m sure you already know, initially the plan is to operate our locomotive with a “hired” tender, either a BR2A or BR1B, whichever is available, when the locomotive is nearing completion. When we get to this stage we will need to have an agreement in place with another owning group before the boiler ticket is started. This will ensure that we don’t have a complete locomotive but no tender available to run with it. When running, the locomotive will have an income which can be used to help fund the new tender build. We will also continue to raise money to ensure that we have sufficient funds to overhaul the locomotive when the time comes.

This feature is intended to keep readers up to date with plans, but also I want to encourage discussion about this topic. We don’t want to create a division amongst our supporters, as this will benefit no-one. I would be very interested to hear comments from you, 76077’s fellow owners and supporters, and the opinion of shareholders particularly will be taken into account. Nevertheless, we would be pleased to hear from you if you feel inclined towards either of the two designs.

We need to make a decision in the near future which type we intend to build, so we can take advantage of the arrangement between Chris Hinton and Tyseley Locomotive Works and start the tender construction. We certainly can’t guarantee that everyone will be in agreement, but majority preference will count considerably towards the final decision. You may feel that I am pushing the 1B design, and to be fair as the person tasked with delivering the new tender it would be my preference but 76077 isn’t my locomotive: collectively, it belongs to many shareholders. Now is your chance to have your say.

Get in touch at info@standard76077.com or write to us at Toddington Standard Locomotive Ltd, Churchward House, Winchcombe Railway Station, Winchcombe Gloucestershire GL54 5LD)